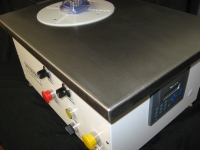

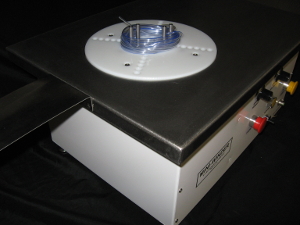

The Mini-Winder and Medi-Winder are used in applications where tubing and wire sets are assembled and packaged. They increase production and packaging output and also prevent hand and wrist Injuries.

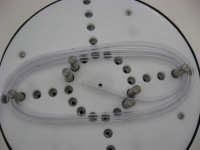

Tubing which has been cut to discrete lengths is placed on the coiling machines. The mandrel rotates the exact number of revolutions required to complete the coil. After it stops, the pins on which the coil was wrapped disappear, enabling the operator to slide the coil into a package.

The Mini-Winder and Medi-Winder have the following features:

- Automatic coiling, the machine counts the number of revolutions and stops. No need to keep your foot on a switch until it stops. No overruns.

- Completely adjustable mandrel to accommodate many coil diameters.

- Produces uniform coil each time 3x faster than conventional methods.

- Packaging fixture enables you to place a pouch or bag on for easy loading.

- All timing and counting functions can be changed easily. PLC controlled and completely programmable. Auto or Jog modes. Pause/Resume button.

- Clean room compatible.

- Mandrel automatically drops down at end of coil count when needed.

- Reversing motor, variable speeds.